WHS risk management is a systematic process of hazard identification, risk assessment, and risk control with the aim of providing healthy and safe conditions for managers, workers, visitors and contractors at Biotao.

As required by the WHS Act, Biotao has adopted a risk management approach to underpin its WHS Management System. This approach involves all managers and workers in identifying hazards, assessing and prioritising risks, implementing control measures and reviewing how effective the control measures are.

All workers are responsible for assisting in managing the particular risks associated with their specific work environment. Risk management strategies used by Biotao include:

- regular hazard inspections of the Biotao environment and client jobsites

- a comprehensive risk register detailing all WHS risks associated with the operation and activities of Biotao

- documented WHS policies and procedures

- risk assessments of newly purchased equipment

- risk assessments for any change to work processes

- hazard, injury, incident reporting procedures

- incident investigations (at the direction of the Manager)

- WHS job safety analysis for Biotao specific activities

Definitions:

- WHS Hazard: Anything which has the potential to cause injury or illness.

- WHS Risk: A WHS risk is the chance of someone becoming injured or ill as a result of a workplace hazard. This significance of the risk is determined by considering the likelihood of it happening and the consequences if it does happen.

- WHS Risk Control: WHS risk control is action taken to eliminate or reduce the likelihood that exposure to a hazard will result in injury or illness to people or damage to property and the environment.

The Risk Management Process

WHS risk management should be undertaken for all activities where there is the potential for harm including:

- before activities commence;

- before the introduction of new equipment, procedures or processes;

- when equipment, procedures or processes are modified.

Step 1: Identify the Hazard

A hazard is a source or potential source of injury, ill health or disease. Hazard identification is the process of identifying all situations and events that could cause injury or illness by examining a work area/task for the purpose of identifying all threats which are ‘inherent in the job’. Tasks can include, but may not be limited to using tools, hazardous chemicals, dealing with people, lifting/moving items and working with animals.

Step 2: Assess the Risk

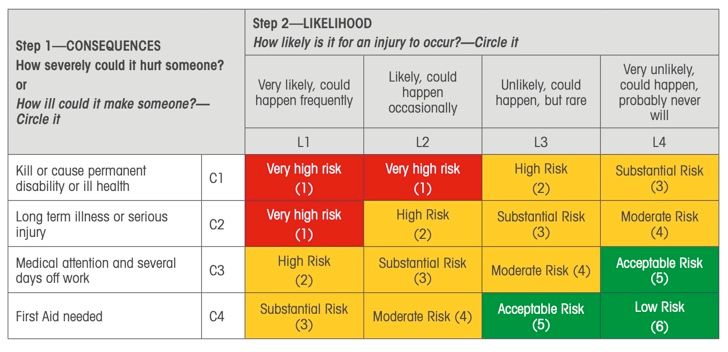

Assessing the risk from a hazard determines its significance. Firstly, consider the consequences should something happen; will it cause a serious injury, illness or death or a minor injury. Secondly, consider how likely is this to occur—very likely, not likely at all or somewhere in between? Some of the things to think about include:

- how often is the task undertaken

- how frequently are people near the hazard

- how many people are near the hazard at a particular time

- has an incident happened before

- have there been any ‘near misses’

Use the table below to determine how significant the risk is.

Where a manager, worker, contractor, or visitor to the workplace identifies a hazard, Biotao requires that it is eliminated or reduced in consultation with the relevant stakeholders.

- Step 1: identify the Consequences—or how severely could it hurt someone

- Step 2: identify the Likelihood—or how likely is it for an injury to occur

- Step 3 & 4: identify the Risk Priority Score—to prioritise your actions

- Step 5: apply the hierarchy of hazard control

- Step 6: identify who, how and when the effectiveness of controls will be checked and reviewed

STEP 3: RISK PRIORITY SCORE IDENTIFIES THE NECESSARY ACTION AND RESPONSE

STEP 4: CONTROL THE HAZARDS

Control the hazards—the aim is to implement the most reliable controls to create a safe workplace rather than simply relying on people to behave safely, following processes or using protective equipment. In many cases, a combination of several control strategies may be the best solution.

Hierarchy of control strategies (in order of preference):

- eliminate the hazard; remove the equipment from use, dispose of unwanted chemicals

- substitute; use a non-hazardous chemical, use a different machine that can do the same task

- isolation; contain noisy machinery within a booth

- engineering controls; design equipment differently, providing lifting devices to minimise manual handling

- administrative processes; task variation, job rotation, training

- personal protective equipment; gloves, hearing protection, eye protection

STEP 5: REVIEW THE PROCESS

Continuously review to monitor and improve control measures and find safer ways of doing things.

Documentation for Risk Assessment

The documentation required for a WHS risk assessment will depend on the operation or activity being assessed. The appropriate WHS Risk Assessment Form must be used when undertaking a risk assessment of the various activities of Biotao.

Utilise the WHS Risk Assessment Proforma and procedure for conducting an assessment.

The WHS Risk Register

The risk assessment data collected from identifying, assessing and controlling risks should be documented on a centralised risk register for Biotao. The risk register holds a list of Biotao key risks that need to be monitored and managed. The risk register is to be managed by the Manager who should be notified if new hazards are identified and controls implemented so that the risk register can be amended.

The Manager is responsible for overseeing the Risk Register, and for ensuring that effective control measures are implemented and that risks are monitored and reviewed on a regular basis.